The interior components of modern vehicles represent far more than mere aesthetic considerations—they form a sophisticated ecosystem that directly influences passenger comfort, safety outcomes, and practical functionality. From advanced ergonomic seating systems to intelligent climate control networks, each interior element plays a crucial role in transforming daily commutes and long-distance journeys into comfortable, secure experiences. Today’s automotive interiors integrate cutting-edge materials science, human factors engineering, and safety technologies to create environments that adapt to individual needs whilst maintaining the highest standards of occupant protection.

Contemporary vehicle interiors have evolved dramatically from basic transportation necessities to comprehensive comfort and safety platforms. The integration of memory foam cushioning, multi-zone climate systems, advanced airbag technologies, and intuitive human-machine interfaces demonstrates how interior components work synergistically to enhance every aspect of the driving experience. Understanding these sophisticated systems helps appreciate the remarkable engineering achievements that make modern vehicles safer, more comfortable, and increasingly user-friendly for drivers and passengers alike.

Ergonomic seating systems and lumbar support technologies

Modern automotive seating systems represent the pinnacle of ergonomic engineering, combining advanced materials science with sophisticated mechanical systems to provide optimal comfort and support. These systems go far beyond traditional upholstery and padding, incorporating multiple layers of technology designed to reduce fatigue, prevent injury, and enhance the overall driving experience. The evolution of seating technology reflects a deep understanding of human anatomy and the specific challenges posed by extended periods of seated travel.

Memory foam cushioning and Multi-Density support layers

Memory foam technology in automotive seating creates a personalised comfort experience by conforming to individual body contours whilst providing consistent support across pressure points. These advanced cushioning systems typically incorporate multiple density layers, with firmer cores providing structural support and softer surface layers offering immediate comfort. The cellular structure of memory foam allows for optimal weight distribution, reducing pressure concentrations that can lead to discomfort during extended journeys.

Multi-density support layers work in concert to address different anatomical requirements across the seating surface. Manufacturers carefully engineer these layers to provide firmer support for the lumbar region whilst offering softer cushioning for shoulders and thighs. This sophisticated approach to cushioning design ensures that occupants maintain proper spinal alignment throughout their journey, significantly reducing the risk of back pain and muscular fatigue.

Adjustable lumbar mechanisms in Mercedes-Benz S-Class and BMW 7 series

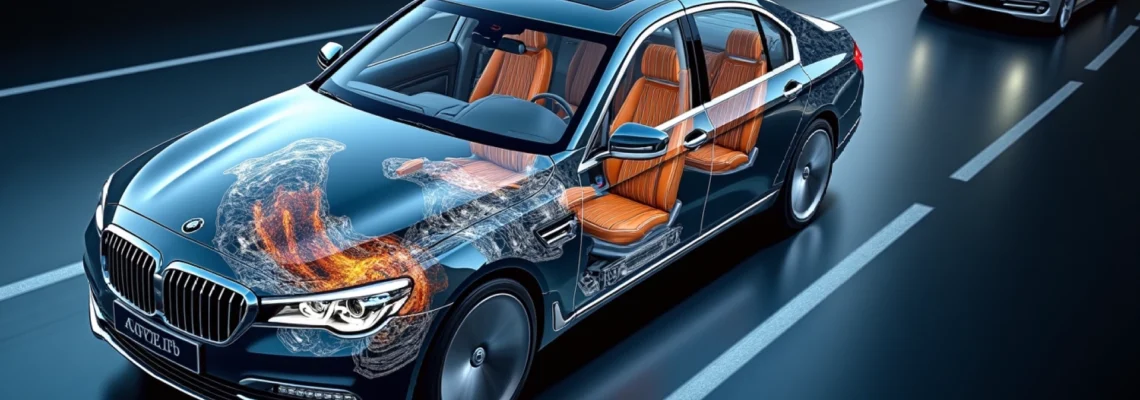

Premium luxury vehicles exemplify the sophistication possible in lumbar support technology, with systems that offer infinitely adjustable positioning to accommodate individual physiological requirements. These mechanisms typically feature pneumatic or electric adjustment systems that can modify both the height and depth of lumbar support, allowing for precise customisation based on individual spinal curvature and comfort preferences.

Advanced lumbar systems in luxury vehicles often incorporate massage functions that provide therapeutic benefits during extended travel. These systems use strategically positioned pneumatic bladders or mechanical actuators to deliver targeted muscle stimulation, improving circulation and reducing tension. The integration of memory functions allows these systems to automatically adjust to preferred settings for different drivers, creating a truly personalised comfort experience.

Ventilated seat technologies and climate control integration

Ventilated seating systems represent a sophisticated approach to thermal comfort management, utilising integrated fans and perforated surfaces to circulate air through the seat cushions and backrests. These systems work in conjunction with the vehicle’s climate control network to maintain optimal seating temperatures regardless of external conditions. The technology particularly excels in hot climates, where traditional seating materials can become uncomfortably warm.

Modern ventilation systems incorporate temperature sensors and automatic climate adjustment capabilities that respond to changing conditions throughout the journey. Some advanced systems can even detect occupant body temperature and adjust ventilation accordingly, creating a truly adaptive comfort environment. The integration with overall climate systems ensures energy efficiency whilst maximising passenger comfort across all seating positions.

Massage function systems in luxury vehicle applications

Automotive massage systems have evolved from simple vibration mechanisms to sophisticated therapeutic platforms that can deliver targeted muscle relief and relaxation. These systems typically incorporate multiple massage programs, including shiatsu, rolling, and percussion techniques, each designed to address specific comfort and wellness requirements. The integration of these systems into vehicle seating demonstrates the industry’s commitment to transforming travel time into opportunities for relaxation and recovery.

Advanced massage systems utilise precise control mechanisms that can target specific muscle groups and adjust intensity based on user preferences. Many systems offer pre-programmed massage sequences designed by therapeutic professionals, ensuring that occupants receive genuine wellness benefits during their journey. The combination of massage functionality with other seating technologies creates a comprehensive comfort platform that addresses both immediate comfort needs and long-term wellness considerations.

Advanced climate control architecture and air distribution networks

Contemporary automotive climate control systems represent sophisticated engineering achievements that go far beyond simple heating and cooling functions. These networks integrate advanced sensors, intelligent control algorithms, and precision air distribution mechanisms to create optimal cabin environments for all occupants. The complexity of modern climate systems reflects the industry’s understanding that thermal comfort significantly impacts driver alertness, passenger satisfaction, and overall journey quality.

Dual-zone and Tri-Zone HVAC system configurations

Multi-zone climate control systems acknowledge that individual thermal preferences vary significantly, even within the same vehicle cabin. Dual-zone systems typically provide independent temperature control for driver and front passenger areas, utilising separate air distribution channels and temperature sensors to maintain personalised comfort zones. These systems incorporate sophisticated damper mechanisms and air mixing chambers that can deliver different temperatures simultaneously to different cabin areas.

Tri-zone systems extend this concept to include independent rear passenger climate control, recognising that thermal conditions can vary significantly between front and rear seating areas. The engineering challenges involved in creating these systems are considerable, requiring precise air distribution networks, multiple temperature sensors, and sophisticated control algorithms that can manage conflicting thermal requirements whilst maintaining overall system efficiency. The result is a climate environment where each occupant can maintain their preferred comfort level without compromising others’ thermal preferences.

HEPA filtration systems and air quality monitoring sensors

Modern vehicles increasingly incorporate hospital-grade HEPA filtration systems that remove microscopic particles, allergens, and pollutants from incoming air. These sophisticated filtration networks can capture particles as small as 0.3 micrometers with 99.97% efficiency, creating cabin air quality that often exceeds external environmental standards. The integration of these systems reflects growing awareness of air quality’s impact on occupant health and comfort, particularly during urban driving conditions.

Air quality monitoring sensors work continuously to assess cabin air conditions, measuring factors including particulate matter concentration, humidity levels, and chemical pollutant presence. These sensors enable automatic filtration system activation when poor external air quality is detected, ensuring consistent cabin air quality regardless of external environmental conditions. Some advanced systems can even detect specific allergens or pollutants and adjust filtration accordingly, providing targeted air quality management for occupants with specific sensitivities.

Heated and cooled surface technologies for steering wheels and armrests

Surface heating and cooling technologies extend climate control benefits to direct contact points, addressing the immediate thermal comfort needs of occupants. Heated steering wheel systems utilise integrated heating elements that can warm the steering wheel surface to comfortable temperatures within seconds, eliminating the discomfort associated with cold steering wheels during winter conditions. These systems typically incorporate temperature sensors and automatic control mechanisms that maintain optimal surface temperatures without overheating.

Cooled surface technologies, whilst less common, provide similar benefits in hot climates by actively cooling contact surfaces to comfortable levels. Armrest heating and cooling systems work in conjunction with seat climate controls to create comprehensive thermal comfort environments. The integration of these technologies with overall climate systems ensures energy efficiency whilst providing immediate comfort benefits that enhance the overall driving experience, particularly during extreme weather conditions.

Defrosting and demisting mechanisms for windscreen and mirror systems

Visibility enhancement systems represent critical safety technologies that ensure clear sight lines under all weather conditions. Modern defrosting systems utilise multiple approaches including heated windscreen elements, targeted air distribution, and rapid heating capabilities that can clear ice and condensation within minutes. These systems incorporate sensors that can detect condensation formation and automatically activate defrosting mechanisms before visibility becomes compromised.

Mirror heating systems work similarly to prevent ice formation and condensation on external mirrors, ensuring consistent visibility of surrounding traffic conditions. Advanced systems can integrate with weather prediction services to pre-activate defrosting mechanisms based on anticipated weather conditions, ensuring optimal visibility from the moment the vehicle is started. The sophistication of these systems demonstrates the industry’s commitment to maintaining safety standards under challenging environmental conditions.

Automotive lighting systems and visibility enhancement components

Interior lighting systems in modern vehicles serve multiple functions beyond basic illumination, contributing significantly to safety, comfort, and usability. These sophisticated networks incorporate LED technology, adaptive brightness control, and intelligent activation mechanisms that respond to ambient conditions and user requirements. Contemporary automotive lighting represents a careful balance between functional illumination, aesthetic enhancement, and energy efficiency considerations.

Ambient lighting systems create comfortable cabin environments that reduce eye strain and enhance the overall travel experience, particularly during night-time driving. These systems typically utilise colour-adjustable LED strips positioned strategically throughout the cabin to provide gentle, non-intrusive illumination that doesn’t interfere with night vision. The integration of ambient lighting with other cabin systems allows for dynamic lighting scenarios that can adapt to different driving conditions and user preferences.

Task-specific lighting addresses practical requirements including map reading, document review, and passenger activities during travel. These focused illumination systems incorporate adjustable beam patterns and intensity controls that provide adequate light for specific tasks without creating glare or distraction for the driver. Modern task lighting systems often include automatic shut-off mechanisms and integration with door sensors to provide appropriate illumination when needed whilst conserving energy when not required.

Safety-oriented lighting systems include door handle illumination, step lighting, and emergency lighting functions that enhance occupant safety during entry, exit, and emergency situations. These systems work in conjunction with vehicle security systems to provide appropriate lighting during different operational scenarios. The integration of these lighting functions with overall vehicle systems ensures that illumination is available when needed whilst maintaining energy efficiency and system longevity.

Dashboard interface design and Human-Machine interaction elements

Contemporary dashboard design represents the convergence of ergonomic principles, technological innovation, and safety requirements into unified interfaces that facilitate intuitive vehicle operation. Modern dashboards must accommodate increasingly complex vehicle systems whilst maintaining clarity, accessibility, and safety for drivers operating under diverse conditions. The evolution from mechanical gauges to digital displays reflects broader technological advancement whilst highlighting the continuing importance of effective human-machine interaction design.

Digital instrument clusters provide customisable information displays that can adapt to individual driver preferences and changing operational requirements. These systems typically incorporate high-resolution displays capable of presenting multiple information layers whilst maintaining readability under various lighting conditions. The flexibility of digital systems allows manufacturers to provide comprehensive vehicle information without cluttering the visual interface, using intelligent information hierarchies that present critical data prominently whilst making supplementary information readily accessible.

Haptic feedback systems enhance dashboard interaction by providing tactile confirmation of control inputs, reducing the need for visual confirmation and thereby supporting safer driving practices. These systems utilise sophisticated actuator technologies that can simulate various tactile sensations, providing intuitive feedback that helps drivers operate controls without taking their eyes off the road. The integration of haptic feedback with touchscreen interfaces creates more intuitive interaction experiences whilst maintaining safety standards.

Voice control integration represents another significant advancement in dashboard interface design, allowing drivers to access vehicle functions through natural language commands. These systems utilise advanced speech recognition algorithms and natural language processing to interpret driver intentions accurately, even in noisy cabin environments. The sophistication of modern voice control systems enables complex multi-step commands whilst providing confirmation and error correction capabilities that ensure reliable operation.

The integration of artificial intelligence in dashboard systems is transforming how drivers interact with their vehicles, creating more intuitive and responsive interfaces that adapt to individual usage patterns and preferences.

Passive safety architecture and occupant protection systems

Passive safety systems represent the most critical aspect of interior automotive engineering, providing life-saving protection during collision events whilst remaining transparent during normal operation. These sophisticated systems integrate advanced materials science, precision engineering, and deployment algorithms to create comprehensive protection networks that adapt to different collision scenarios and occupant characteristics. The continuous evolution of passive safety technology reflects the industry’s unwavering commitment to occupant protection and injury mitigation.

Airbag deployment mechanisms and Multi-Stage inflation technologies

Modern airbag systems utilise sophisticated sensor networks and deployment algorithms that can analyse collision characteristics and occupant positioning within milliseconds to determine optimal inflation strategies. Multi-stage inflation systems provide graduated deployment responses that match the severity and characteristics of specific collision events, ensuring appropriate protection whilst minimising deployment-related injuries. These systems represent remarkable engineering achievements that balance protection effectiveness with deployment safety.

Advanced airbag systems incorporate occupant detection capabilities that can identify passenger size, position, and seat belt usage to optimise deployment characteristics. These systems utilise weight sensors, seat position monitors, and even visual recognition technologies to ensure that airbag deployment provides optimal protection for each specific occupant scenario. The sophistication of these detection systems enables deployment suppression for unoccupied seats or inappropriate occupant positions, preventing unnecessary deployments whilst ensuring protection when needed.

Seatbelt pretensioner systems and load limiters

Seatbelt pretensioner systems work in conjunction with airbag deployment to position occupants optimally for collision protection, utilising explosive charges or mechanical systems to instantly remove slack from seatbelt systems during collision events. These systems ensure that occupants are properly positioned relative to deploying airbags, maximising protection effectiveness whilst minimising injury risk. The precision required in pretensioner operation demonstrates the sophisticated engineering involved in passive safety systems.

Load limiter mechanisms prevent excessive seatbelt forces that could cause chest injuries during severe collision events, utilising controlled material deformation or mechanical systems to manage restraint forces. These systems balance the competing requirements of occupant restraint and injury prevention, allowing controlled occupant movement that reduces chest loading whilst maintaining overall restraint effectiveness. The integration of load limiters with pretensioner systems creates comprehensive restraint platforms that adapt to collision characteristics and occupant requirements.

Crumple zone integration with interior structural components

Interior structural components work in conjunction with exterior crumple zones to manage collision energy whilst maintaining occupant space integrity. These systems utilise sophisticated material engineering and structural design to create progressive energy absorption characteristics that protect occupants by managing collision forces. The integration of interior and exterior structural elements demonstrates the holistic approach required for effective passive safety design.

Advanced materials including high-strength steels and composite structures enable interior components to maintain structural integrity under extreme loading conditions whilst contributing to overall energy management strategies. These materials undergo extensive testing to ensure consistent performance under various collision scenarios, temperature conditions, and aging effects. The careful selection and application of these materials reflects the critical importance of structural integrity in passive safety performance.

Whiplash protection systems in volvo WHIPS and similar technologies

Whiplash protection systems address rear-impact collision scenarios by managing occupant movement during the initial phases of collision events. These systems typically utilise seat back mechanisms that allow controlled rearward movement whilst providing graduated support that reduces neck loading. The engineering challenges involved in creating effective whiplash protection include balancing normal comfort requirements with collision performance needs.

Advanced whiplash protection systems incorporate active head restraint mechanisms that deploy during rear-impact events to provide immediate neck support. These systems utilise collision detection sensors and mechanical deployment mechanisms that position head restraints optimally for neck protection within the critical first moments of rear-impact collisions. The sophistication of these systems demonstrates the industry’s commitment to addressing specific injury mechanisms through targeted engineering solutions.

Effective whiplash protection requires precise timing and positioning of protective elements, representing some of the most sophisticated mechanical systems in modern vehicles.

Storage solutions and practical interior configurations

Contemporary vehicle storage systems address the diverse practical requirements of modern mobility through sophisticated design solutions that maximise utility whilst maintaining safety and aesthetic standards. These systems must accommodate everything from personal electronics and beverages to emergency equipment and cargo, all whilst ensuring that stored items don’t become projectiles during sudden manoeuvres or collision events. The evolution of storage solutions reflects changing lifestyle requirements and the increasing role of vehicles as mobile offices and entertainment platforms.

Modular storage systems provide flexible accommodation for varying cargo requirements through reconfigurable compartments and adjustable mounting systems. These systems utilise sophisticated mechanical mechanisms that allow storage configurations to adapt to specific load requirements whilst maintaining structural integrity and safety standards. The engineering challenges involved in creating robust yet flexible storage systems require careful consideration of weight distribution, structural loading, and accessibility requirements across diverse usage scenarios.

Secure storage solutions address the growing need for valuable item protection through integrated locking mechanisms and concealed compartment designs. These systems provide theft deterrent capabilities whilst maintaining convenient access for authorised users. Advanced secure storage systems may incorporate biometric access controls or integration with vehicle security systems to provide comprehensive protection for valuable items including laptops, documents, and personal electronics.

Climate-controlled storage compartments extend beyond simple cooling to provide optimal preservation conditions for specific item categories including medications, electronics, and perishable goods. These systems utilise sophisticated temperature and humidity control mechanisms that can maintain stable environmental conditions regardless of external weather or cabin climate settings. The integration of these systems with overall vehicle climate networks ensures energy efficiency whilst providing specialised storage capabilities that address modern lifestyle requirements.

The future of automotive storage

solutions extends beyond traditional fixed configurations to encompass adaptive systems that can reconfigure automatically based on detected cargo requirements and usage patterns. These intelligent storage platforms utilise sensor networks and motorised mechanisms to optimise compartment sizes and accessibility, representing the next evolution in automotive utility design. The integration of artificial intelligence enables these systems to learn from user behaviour patterns and automatically prepare optimal storage configurations for different journey types or passenger requirements.

Emergency equipment storage represents a critical aspect of practical interior design, requiring systems that keep essential safety items accessible yet secure during normal operation. Modern vehicles incorporate dedicated compartments for first aid kits, emergency tools, and communication devices, designed to remain accessible even after collision events or system failures. These storage solutions must meet stringent safety standards whilst providing intuitive access during high-stress emergency situations.

The integration of charging infrastructure within storage systems addresses the ubiquitous need for electronic device power management during travel. Advanced storage compartments incorporate wireless charging platforms, multiple USB outlets, and even AC power connections that enable passengers to maintain device functionality throughout extended journeys. These systems utilise sophisticated power management algorithms that balance charging requirements with vehicle electrical system capacity, ensuring reliable operation without compromising essential vehicle functions.

Accessibility considerations in storage design ensure that all occupants, regardless of physical capabilities or seating position, can access essential storage functions safely and conveniently. These design principles incorporate reach zone analysis, ergonomic handle design, and intuitive operation mechanisms that accommodate diverse user requirements. The implementation of universal design principles in storage systems reflects the industry’s commitment to inclusive mobility solutions that serve all users effectively.

The evolution of automotive storage systems demonstrates how practical requirements drive innovation, creating solutions that enhance daily usability whilst maintaining the sophisticated safety and comfort standards expected in modern vehicles.

Advanced storage materials utilise antimicrobial coatings and easy-clean surfaces that maintain hygiene standards even under intensive use conditions. These materials resist staining, odour absorption, and bacterial growth, ensuring that storage areas remain pleasant and hygienic throughout the vehicle’s operational life. The selection of appropriate materials requires balancing durability, maintainability, and environmental considerations whilst meeting automotive industry standards for outgassing and chemical emissions.

Cargo management systems extend storage functionality through integrated restraint mechanisms that prevent load shifting during vehicle operation. These systems utilise adjustable barriers, retention nets, and securing points that can accommodate diverse cargo types whilst preventing movement that could affect vehicle handling or occupant safety. The engineering sophistication required to create effective cargo restraint systems demonstrates the comprehensive approach modern manufacturers take to practical interior functionality.

Smart storage systems incorporate inventory management capabilities that can track stored items and provide reminders or alerts related to storage contents. These systems utilise RFID technology, weight sensors, or visual recognition systems to maintain awareness of storage contents, enabling features such as expiration date tracking for emergency supplies or theft alerts for valuable items. The integration of these capabilities with vehicle communication systems enables remote monitoring and management of storage contents, representing a significant advancement in practical vehicle utility.

The future development of automotive interior storage continues to evolve toward even greater integration with digital lifestyle requirements, autonomous vehicle configurations, and sustainable material applications. As vehicles transition toward autonomous operation, storage systems must adapt to support new usage patterns including mobile office configurations, entertainment platforms, and extended travel scenarios. These evolving requirements drive continued innovation in storage system design, materials science, and integration technologies that will define the next generation of automotive interior utility solutions.