The modern automotive engine represents one of humanity’s most sophisticated mechanical achievements, transforming chemical energy into kinetic motion through precisely orchestrated components. Whether you’re driving a compact city car or a high-performance sports vehicle, the fundamental principles governing engine operation remain remarkably consistent. Each component within the engine bay serves a critical function, working in perfect harmony to deliver the power, efficiency, and reliability that drivers expect from their vehicles.

Understanding these essential engine parts isn’t merely academic knowledge—it empowers you to make informed decisions about maintenance, recognise potential issues before they become costly repairs, and appreciate the remarkable engineering that propels you down the road. From the robust engine block that houses the combustion chambers to the intricate valve train systems that control airflow, every component has been refined through decades of automotive evolution.

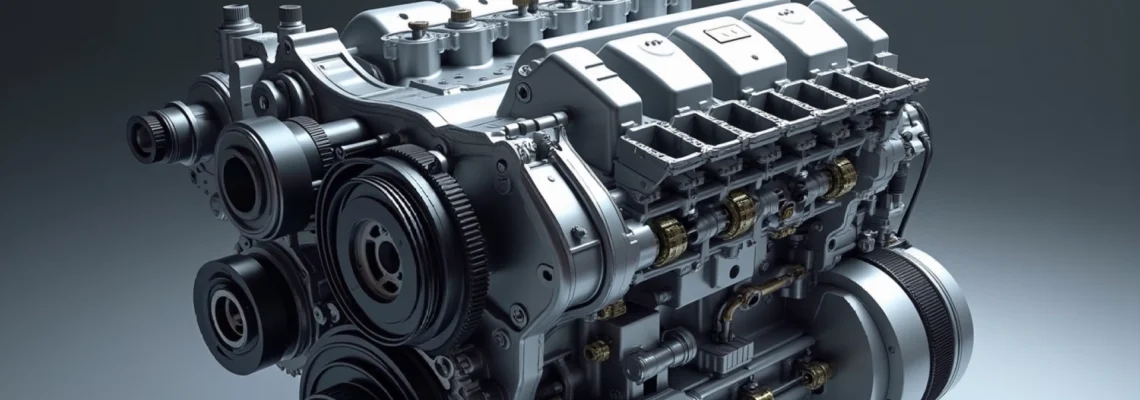

Internal combustion engine block and cylinder assembly components

The engine block serves as the foundation of any internal combustion engine, housing the cylinders where the magic of combustion occurs. This substantial component must withstand extreme pressures, temperatures, and mechanical stresses while maintaining structural integrity throughout the engine’s operational life. The block’s design directly influences engine performance, durability, and thermal characteristics, making it one of the most critical elements in the entire powertrain system.

Cast iron vs aluminium engine block construction and thermal properties

Traditional cast iron engine blocks have dominated automotive manufacturing for decades due to their exceptional durability and cost-effectiveness. Cast iron blocks exhibit superior wear resistance, particularly in high-mileage applications, and provide excellent dampening of engine vibrations. The material’s thermal properties allow for consistent heat distribution, though the increased weight can negatively impact fuel economy and overall vehicle dynamics.

Modern aluminium engine blocks have revolutionised automotive design by offering significant weight reductions—typically 40-50% lighter than equivalent cast iron blocks. This weight saving translates directly into improved fuel efficiency and enhanced vehicle handling characteristics. Aluminium’s superior thermal conductivity enables more efficient heat dissipation, allowing engines to run at optimal temperatures more consistently. However, aluminium blocks require more sophisticated manufacturing processes and may exhibit different expansion characteristics compared to cast iron alternatives.

Cylinder bore specifications and piston ring sealing mechanisms

Cylinder bore dimensions represent critical specifications that determine an engine’s displacement and performance characteristics. The bore diameter, combined with stroke length, establishes the total cubic capacity of the engine. Modern manufacturing techniques achieve bore tolerances within micrometres, ensuring optimal piston clearances and preventing excessive blow-by gases from compromising combustion efficiency.

Piston ring sealing mechanisms form the crucial barrier between the combustion chamber and crankcase. The top compression ring bears the primary responsibility for sealing combustion gases, while the second ring provides backup sealing and assists with oil control. The oil control ring assembly manages lubrication distribution across the cylinder walls whilst preventing excessive oil consumption. Ring tension, gap specifications, and surface treatments all contribute to effective sealing performance throughout the engine’s service life.

Crankcase ventilation systems and oil gallery networks

Positive crankcase ventilation (PCV) systems manage the inevitable blow-by gases that escape past piston rings during combustion. These systems prevent pressure buildup within the crankcase whilst routing vapours back through the intake system for reburning. Modern PCV valves incorporate sophisticated flow control mechanisms that adjust ventilation rates based on engine load and operating conditions, optimising both emissions control and engine performance.

Oil gallery networks within the engine block function as the circulatory system, delivering pressurised lubricant to critical bearing surfaces, camshaft assemblies, and hydraulic components. These precisely machined passages must maintain adequate flow rates whilst withstanding oil pressure fluctuations. Strategic placement of oil galleries ensures that even the most remote engine components receive sufficient lubrication under all operating conditions, from cold starts to high-performance driving scenarios.

Cylinder head gasket materials and torque specifications

Cylinder head gaskets represent one of the most demanding sealing applications in automotive engineering, simultaneously containing combustion pressures, coolant passages, and oil circuits. Modern multi-layer steel (MLS) gaskets have largely replaced traditional composite materials due to their superior durability and sealing capabilities. MLS gaskets feature multiple steel layers with specialised coatings that accommodate thermal expansion whilst maintaining consistent sealing pressure across the combustion chamber.

Torque specifications for cylinder head bolts follow precise sequences and values to ensure uniform clamping forces across the gasket surface. Many modern engines utilise torque-to-yield (TTY) bolts that stretch during installation, providing more consistent clamping loads and better accommodation of thermal cycling. The installation sequence typically follows a spiral pattern from the centre outward, ensuring gradual and even compression of the gasket material.

Crankshaft assembly and rotating engine components

The crankshaft assembly transforms the linear motion of pistons into rotational energy that ultimately powers your vehicle’s wheels. This remarkable piece of engineering must handle enormous forces whilst maintaining precise balance and smooth rotation. The crankshaft’s design parameters, including journal sizes, stroke length, and counterweight positioning, directly influence engine characteristics such as torque delivery, maximum RPM capability, and overall refinement levels.

The crankshaft experiences forces equivalent to several tonnes during peak combustion events, yet must rotate smoothly at speeds exceeding 6,000 RPM while maintaining dimensional stability throughout its operational life.

Forged steel crankshaft design and main bearing journals

Forged steel crankshafts represent the pinnacle of durability in high-performance applications, offering superior grain structure and fatigue resistance compared to cast alternatives. The forging process aligns the steel’s grain structure with the crankshaft’s contours, creating natural stress-flow patterns that enhance structural integrity. These crankshafts typically feature induction-hardened journal surfaces that resist wear whilst maintaining the core’s toughness and flexibility.

Main bearing journals provide the primary support points where the crankshaft rotates within the engine block. These precisely machined surfaces must maintain extremely tight tolerances—typically within 0.0001 inches—to ensure proper oil film thickness and bearing longevity. Journal surface finish specifications are equally critical, with specific roughness values required to promote proper oil film formation whilst minimising friction losses.

Connecting rod big end and small end bearing technologies

Connecting rod bearings utilise sophisticated tri-metal construction featuring a steel backing, copper-lead intermediate layer, and specialised overlay materials. The overlay composition—often incorporating polymers or exotic alloys—provides the actual bearing surface that contacts the crankshaft journal. These materials must accommodate minor misalignments whilst providing low friction characteristics and excellent seizure resistance under extreme loading conditions.

Small end bearings at the piston pin connection typically employ bronze bushings or needle roller bearings, depending on the application requirements. Bronze bushings offer simplicity and cost-effectiveness whilst providing adequate durability for most applications. High-performance engines may utilise needle roller bearings that reduce friction losses and accommodate higher loads, though they require more precise manufacturing tolerances and assembly procedures.

Piston crown design and compression ring configuration

Piston crown geometry plays a crucial role in combustion chamber shape and flame propagation characteristics. Flat-top pistons maximise compression ratio and provide uniform flame travel, whilst dished crowns accommodate higher boost pressures in forced induction applications. Some performance pistons feature valve reliefs or complex contours that optimise combustion whilst preventing valve-to-piston interference during high-RPM operation.

Compression ring configurations have evolved significantly with modern low-friction designs featuring thinner ring sections and advanced surface treatments. The top ring typically measures 1.0-1.2mm in thickness on modern engines, compared to 2.0mm or more on older designs. These thinner rings reduce friction losses whilst maintaining effective sealing through improved conformability to cylinder wall irregularities. Ring coating technologies, including diamond-like carbon (DLC) and various nitrides, further enhance durability and reduce friction.

Harmonic balancer and flywheel assembly integration

Harmonic balancers, also known as dampers, control torsional vibrations within the crankshaft that occur due to combustion impulses and rotating mass imbalances. These devices typically feature an outer ring connected to the crankshaft pulley through a elastomeric or viscous coupling medium. The coupling material absorbs and dissipates vibrational energy whilst allowing the outer ring to oscillate out of phase with the crankshaft’s torsional vibrations.

Flywheel assemblies serve multiple functions beyond simply storing rotational energy between combustion events. The flywheel provides the mounting surface for the clutch assembly in manual transmissions or the flexplate connection in automatic transmissions. Modern flywheel designs often incorporate dual-mass configurations that isolate drivetrain vibrations and improve comfort whilst maintaining adequate rotational inertia for smooth engine operation.

Valve train system and camshaft operation mechanisms

The valve train system orchestrates the precise timing of intake and exhaust events that enable efficient engine breathing. This complex assembly must operate reliably at thousands of cycles per minute whilst maintaining accurate timing relationships and minimal friction losses. The evolution from simple mechanical systems to sophisticated variable timing mechanisms represents one of the most significant advances in internal combustion engine technology, enabling modern engines to deliver both performance and efficiency across a broad operating range.

DOHC vs SOHC camshaft configuration and timing chain systems

Double overhead camshaft (DOHC) configurations provide independent control of intake and exhaust valve operations, enabling more aggressive cam profiles and improved high-RPM breathing characteristics. DOHC designs typically feature four valves per cylinder, increasing total valve area and improving volumetric efficiency. The separate camshafts allow intake and exhaust timing to be optimised independently, contributing to broader torque curves and higher peak power output.

Single overhead camshaft (SOHC) systems offer simplicity and cost advantages whilst maintaining adequate performance for many applications. These designs typically utilise rocker arms or finger followers to operate the valves, requiring fewer components and simpler manufacturing processes. Modern SOHC systems can achieve impressive performance levels through careful design optimisation, though they generally cannot match the ultimate capabilities of DOHC configurations in high-performance applications.

Timing chain systems have largely replaced timing belts in modern engines due to their superior durability and reduced maintenance requirements. Modern chains feature sophisticated tensioning systems that automatically maintain proper chain tension throughout the engine’s service life. Chain stretch monitoring systems can even adjust valve timing to compensate for gradual elongation, maintaining optimal performance over extended periods.

Hydraulic lifter operation and valve clearance adjustment

Hydraulic lifters, or lash adjusters, automatically maintain zero valve clearance through oil pressure-activated mechanisms. These devices incorporate a small piston within the lifter body that extends under oil pressure to eliminate clearance between the camshaft and valve train components. This automatic adjustment eliminates the need for periodic valve clearance adjustments whilst reducing noise and wear throughout the valve train system.

The hydraulic lifter’s operation depends on precisely controlled oil flow through small orifices and check valves within the lifter body. During the lift phase, trapped oil becomes incompressible, effectively creating a solid connection between the camshaft and valve. When the cam returns to its base circle, oil pressure refills the lifter chamber, maintaining constant contact whilst accommodating thermal expansion and wear throughout the valve train components.

Variable valve timing systems: VTEC and VVT-i technologies

Honda’s VTEC (Variable Valve Timing and Lift Electronic Control) system revolutionised performance engine technology by providing multiple camshaft profiles within a single engine. The system utilises hydraulically activated locking pins that engage alternate cam lobes at predetermined RPM points, effectively changing the engine’s breathing characteristics. This technology enables engines to provide excellent low-RPM tractability whilst delivering impressive high-RPM performance through more aggressive valve timing and lift profiles.

Toyota’s VVT-i (Variable Valve Timing with intelligence) system continuously adjusts intake camshaft timing relative to the crankshaft position using hydraulically controlled cam phasers. The system responds to engine load, RPM, and temperature inputs to optimise valve timing for current operating conditions. This continuous adjustment capability provides benefits across the entire RPM range, improving fuel economy, reducing emissions, and enhancing performance compared to fixed timing systems.

Intake and exhaust valve materials and seat machining tolerances

Modern intake valves typically utilise stainless steel alloys that provide excellent corrosion resistance and adequate strength for the relatively low-temperature intake environment. These materials must withstand constant thermal cycling whilst maintaining dimensional stability and sealing integrity. Surface treatments, including hard chrome plating or nitride coatings, enhance wear resistance and reduce friction against valve guides and seats.

Exhaust valves operate in significantly more demanding environments, requiring exotic alloy compositions including Inconel or other heat-resistant materials. These superalloys maintain strength at extreme temperatures whilst resisting oxidation and thermal fatigue. Many high-performance exhaust valves feature hollow stems filled with sodium coolant that enhances heat transfer from the valve head to the stem and guide areas. Seat machining tolerances typically range from 0.0005 to 0.001 inches, ensuring proper sealing whilst accommodating thermal expansion differences between valve and seat materials.

Fuel delivery and air intake system components

Modern fuel delivery systems have evolved from simple carburettors to sophisticated electronic injection systems capable of precise fuel metering under all operating conditions. These systems must deliver the exact fuel quantity required for optimal combustion whilst maintaining consistent pressure and atomisation characteristics. The integration of advanced sensors and control strategies enables modern engines to achieve remarkable efficiency and emissions performance whilst delivering responsive throttle characteristics.

Air intake systems complement fuel delivery by ensuring adequate airflow to support combustion requirements across the engine’s operating range. The design of intake manifolds, throttle bodies, and filtering systems directly impacts engine breathing characteristics and ultimately affects power delivery, fuel economy, and emissions performance. Modern variable-geometry intake systems can optimise airflow characteristics for different operating conditions, providing broad torque curves and improved efficiency.

Electronic throttle control systems have replaced traditional mechanical linkages in most modern vehicles, providing more precise throttle response and enabling advanced features such as cruise control integration and stability management intervention. These drive-by-wire systems utilise position sensors and electric motor actuators to control throttle opening based on accelerator pedal position and various engine management inputs. The elimination of mechanical connections allows for more sophisticated control strategies whilst reducing complexity in the engine bay.

Modern fuel injection systems can achieve injection timing accuracy within fractions of a degree of crankshaft rotation, enabling multiple injection events per combustion cycle to optimise mixture preparation and reduce emissions formation.

High-pressure fuel pumps in direct injection systems operate at pressures exceeding 2,000 PSI, requiring robust construction and precise manufacturing tolerances. These pumps typically utilise cam-driven mechanisms that synchronise fuel pressure generation with engine operation, ensuring consistent fuel delivery regardless of operating conditions. The integration of fuel rail pressure sensors enables closed-loop pressure control that maintains optimal injection characteristics whilst minimising fuel consumption and emissions.

Ignition system elements and combustion control mechanisms

Contemporary ignition systems represent a remarkable advancement from the simple points-and-condenser systems of earlier automotive eras. Modern systems deliver precisely timed, high-energy sparks that initiate combustion with exceptional accuracy and reliability. The evolution from distributor-based systems to individual coil-on-plug configurations has eliminated many potential failure points whilst enabling more sophisticated timing control strategies that optimise performance across varying operating conditions.

Spark plug technology has advanced significantly, with modern designs featuring exotic electrode materials and sophisticated heat range characteristics. Platinum and iridium electrodes provide extended service life whilst maintaining consistent ignition performance throughout their operational period. These precious metal electrodes resist erosion and maintain sharp edges that promote reliable spark formation even under adverse conditions such as fuel contamination or extreme operating temperatures.

Ignition coil design has transitioned from single-coil distributorless systems to individual coils mounted directly above each spark plug. This coil-on-plug configuration eliminates high-voltage spark plug wires and their associated energy losses whilst enabling independent timing control for each cylinder. Modern coils can generate voltages exceeding 40,000 volts whilst maintaining compact dimensions and reliable operation throughout extreme temperature ranges.

Electronic ignition control modules process inputs from multiple sensors to determine optimal ignition timing for current operating conditions. These systems consider factors including engine load, RPM, temperature, and knock sensor feedback to advance or retard timing for maximum efficiency whilst preventing detonation. Advanced systems can even adjust timing on a cylinder-by-cylinder basis to accommodate manufacturing tolerances and individual cylinder characteristics, maximising both performance and longevity.

Knock detection systems utilise sophisticated sensors that monitor combustion noise signatures to identify the onset of detonation before engine damage occurs. These piezoelectric sensors can detect the specific frequency signatures associated with abnormal combustion, enabling the engine management system to retard timing or adjust fuel delivery to prevent damage. The integration

of knock sensor feedback allows modern engines to operate closer to their optimal efficiency point whilst maintaining protection against destructive detonation under all operating conditions.

Cooling system and engine temperature regulation components

The engine cooling system represents a critical balance between maintaining optimal operating temperatures and preventing overheating damage. Modern cooling systems must accommodate the intense heat generation of high-performance engines whilst providing consistent temperature control across varying ambient conditions and operating loads. The sophistication of contemporary cooling systems extends far beyond simple water circulation, incorporating advanced materials, electronic controls, and sophisticated heat exchange technologies that maximise efficiency whilst minimising energy consumption.

Radiator design has evolved significantly from simple tube-and-fin configurations to complex multi-pass designs featuring advanced core materials and optimised airflow characteristics. Modern radiators utilise aluminium construction throughout, providing superior heat transfer properties whilst reducing weight compared to traditional brass and copper designs. The integration of plastic tanks with aluminium cores offers manufacturing cost advantages whilst maintaining adequate durability for most applications, though high-performance engines may require all-aluminium construction for maximum heat dissipation capability.

Water pump technology has transitioned from simple centrifugal designs to sophisticated variable-flow systems that adjust coolant circulation based on engine temperature and operating conditions. Electric water pumps are increasingly common, offering precise flow control independent of engine RPM whilst reducing parasitic losses that can impact fuel economy. These systems can continue operating after engine shutdown to prevent localised overheating in critical areas, particularly important in turbocharged applications where post-shutdown heat soak can damage components.

Thermostat operation controls coolant flow through the radiator circuit, maintaining optimal engine temperature whilst enabling rapid warm-up from cold starts. Modern thermostats feature sophisticated wax-actuated mechanisms that provide precise temperature control with minimal hysteresis. Some advanced systems incorporate electronically controlled thermostats that can adjust opening temperatures based on operating conditions, optimising warm-up times whilst maintaining precise temperature control under varying loads.

Modern cooling systems must dissipate heat equivalent to the power output of several household electric heaters whilst maintaining engine temperatures within a narrow window of just 15-20 degrees Celsius for optimal efficiency and longevity.

Coolant formulations have advanced dramatically, with modern extended-life coolants providing corrosion protection and heat transfer enhancement for periods exceeding 150,000 miles. These organic acid technology (OAT) coolants eliminate the need for traditional silicate and phosphate additives whilst providing superior protection for aluminium components. The integration of hybrid organic acid technology (HOAT) provides compatibility with mixed-metal cooling systems whilst maintaining extended service intervals and improved heat transfer characteristics.

Cooling fan systems have evolved from simple engine-driven designs to sophisticated electric systems featuring variable-speed control and advanced airflow management. Modern systems utilise brushless DC motors that provide precise speed control whilst minimising electrical consumption and noise generation. The integration of multiple fans with independent control enables optimised airflow distribution across the radiator surface whilst providing redundancy in critical applications. Electronic fan controllers monitor coolant temperature, air conditioning operation, and vehicle speed to determine optimal fan operation, maximising cooling efficiency whilst minimising energy consumption and noise levels.